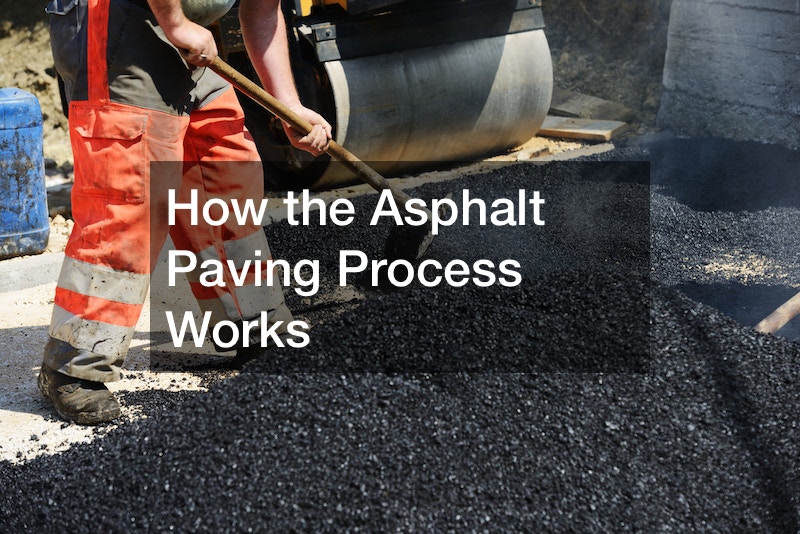

Have you ever wondered how asphalt pavement is installed on roads, driveways, and parking lots? The paving process is fairly simple. Here’s a basic overview of how it works.

The first step in the process is to make sure the area being paved is clean and free of debris. The paving company sweeps away loose items like rocks or stones that would cause lumps in the pavement. They also remove any plants from the root and spray herbicide to ensure that no new plants grow under the asphalt and damage it.

Next, the paving company lays down a base rock aggregate and level or grade it based on what the client prefers. This base rock aggregate is then flattened using a three-ton vibratory roller. Colas liquid is then added to bond the base layer to the new asphalt.

After adding the Colas liquid, it’s time for the hot mix asphalt. The vibratory roller compacts most of this new layer, but a hand compactor or heavy tamping is used to flatten down any corners or hard-to-reach areas.

After the paving company has finished all of the above steps, the asphalt paving process is complete. As long as the pavement gets the client’s seal of approval, it will be ready to drive on once it has dried.

.